| Availability: | |

|---|---|

| Quantity: | |

din582

GS

GSEN001

Product Name | Din582 Metric M6 Stainless Steel Eye Nut for Lifting |

Material | Stainless Steel 304/316/316L |

OEM/Custom | YES |

Feature | 1.Corrosion resistant 2.Excellent life cycle 3.Environmentally friendly 4.High-Performance Fastening |

Standard Available | GB, DIN, ISO, ANSI, ASME, IFI, JIS, BSW, AS, Q, HJ, BS, PEN |

Material Available | Stainless Steel Titanium and Titanium Alloy Aluminum |

Packing | Box+Carton +Pallet or as per client's requirement |

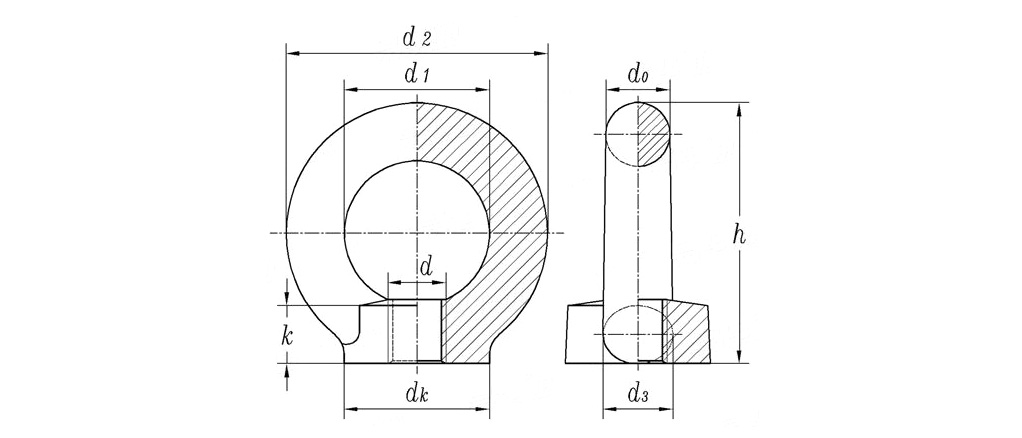

Specification

| Thread size | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | M72×6 | M80×6 | M100×6 | ||

| d | ||||||||||||||

| dk | Nominal | 75 | 85 | 85 | 100 | 100 | 110 | 110 | 120 | 120 | 150 | 170 | 190 | |

| Min | 74.3 | 84.3 | 84.3 | 99.2 | 99.2 | 108.9 | 108.9 | 118.9 | 118.9 | 148.8 | 168.5 | 188.5 | ||

| Max | 76.5 | 86.5 | 86.5 | 101.7 | 101.7 | 112.1 | 112.1 | 122.1 | 122.1 | 152.4 | 173 | 193 | ||

| d2 | Nominal | 126 | 144 | 144 | 166 | 166 | 184 | 184 | 206 | 206 | 260 | 296 | 330 | |

| Min | 125.2 | 143.2 | 143.2 | 164.9 | 164.9 | 182.8 | 182.8 | 204.8 | 204.8 | 258.5 | 294.3 | 328.3 | ||

| Max | 127.7 | 145.7 | 145.7 | 168.1 | 168.1 | 186.4 | 186.4 | 208.4 | 208.4 | 263 | 299.3 | 333.3 | ||

| d1 | Nominal | 70 | 80 | 80 | 90 | 90 | 100 | 100 | 110 | 110 | 140 | 160 | 180 | |

| Min | 68.5 | 78.5 | 78.5 | 88.3 | 88.3 | 98.1 | 98.1 | 107.9 | 107.9 | 137.6 | 157.3 | 177 | ||

| Max | 70.7 | 80.7 | 80.7 | 90.8 | 90.8 | 100.9 | 100.9 | 111.1 | 111.1 | 141.2 | 161.3 | 181.5 | ||

| k | Nominal | 30 | 35 | 35 | 40 | 40 | 45 | 45 | 50 | 50 | 60 | 70 | 80 | |

| Min | 29.3 | 34.3 | 34.3 | 39.2 | 39.2 | 44.1 | 44.1 | 49.1 | 49.1 | 58.9 | 68.8 | 78.8 | ||

| Max | 31.3 | 36.5 | 36.5 | 41.7 | 41.7 | 46.9 | 46.9 | 51.9 | 51.9 | 62.1 | 72.4 | 82.4 | ||

| h | Nominal | 128 | 147 | 147 | 168 | 168 | 187 | 187 | 208 | 208 | 260 | 298 | 330 | |

| Min | 127.2 | 146.2 | 146.2 | 166.9 | 166.9 | 185.8 | 185.8 | 206.8 | 206.8 | 258.5 | 296.3 | 328.3 | ||

| Max | 129.7 | 148.7 | 148.7 | 170.1 | 170.1 | 189.4 | 189.4 | 210.4 | 210.4 | 263 | 301.3 | 333.3 | ||

| d0 | Nominal | 28 | 32 | 32 | 38 | 38 | 42 | 42 | 48 | 48 | 60 | 68 | 75 | |

| Min | 27.3 | 31.3 | 31.3 | 37.2 | 37.2 | 41.1 | 41.1 | 47.1 | 47.1 | 58.9 | 66.8 | 73.8 | ||

| Max | 29.3 | 33.3 | 33.3 | 39.7 | 39.7 | 43.9 | 43.9 | 49.9 | 49.9 | 62.1 | 70.4 | 77.4 | ||

| d3 | Nominal | 32 | 38 | 38 | 46 | 46 | 50 | 50 | 58 | 58 | 72 | 80 | 88 | |

| Min | 31.3 | 37.3 | 37.3 | 45.2 | 45.2 | 49.1 | 49.1 | 57.1 | 57.1 | 70.9 | 78.8 | 86.8 | ||

| Max | 33.3 | 39.5 | 39.5 | 47.7 | 47.7 | 51.9 | 51.9 | 59.9 | 59.9 | 74.1 | 82.4 | 90.4 | ||

| Single weight (steel)≈kg | 2.08 | 3.15 | 3.11 | 5.08 | 5.02 | 6.79 | 6.69 | 9.43 | 9.3 | 18.5 | 27.3 | 36.4 | ||

| Thread size | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | ||

| d | |||||||||||||||

| dk | Nominal | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 50 | 50 | 65 | 65 | 75 | |

| Min | 19.5 | 19.5 | 24.5 | 29.5 | 34.5 | 34.5 | 39.5 | 39.5 | 49.4 | 49.4 | 64.3 | 64.3 | 74.3 | ||

| Max | 20.9 | 20.9 | 25.9 | 30.9 | 36.1 | 36.1 | 41.1 | 41.1 | 51.2 | 51.2 | 66.3 | 66.3 | 76.5 | ||

| d2 | Nominal | 36 | 36 | 45 | 54 | 63 | 63 | 72 | 72 | 90 | 90 | 108 | 108 | 126 | |

| Min | 35.5 | 35.5 | 44.5 | 53.5 | 62.5 | 62.5 | 71.5 | 71.5 | 89.4 | 89.4 | 107.3 | 107.3 | 125.2 | ||

| Max | 37.1 | 37.1 | 46.1 | 55.1 | 64.1 | 64.1 | 73.1 | 73.1 | 91.2 | 91.2 | 109.5 | 109.5 | 127.7 | ||

| d1 | Nominal | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 50 | 50 | 60 | 60 | 70 | |

| Min | 19.1 | 19.1 | 24.1 | 29.1 | 33.9 | 33.9 | 38.9 | 38.9 | 48.8 | 48.8 | 58.7 | 58.7 | 68.5 | ||

| Max | 20.5 | 20.5 | 25.5 | 30.5 | 35.5 | 35.5 | 40.5 | 40.5 | 50.6 | 50.6 | 60.7 | 60.7 | 70.7 | ||

| k | Nominal | 8.5 | 8.5 | 10 | 11 | 13 | 13 | 16 | 16 | 20 | 20 | 25 | 25 | 30 | |

| Min | 8 | 8 | 9.5 | 10.5 | 12.5 | 12.5 | 15.5 | 15.5 | 19.5 | 19.5 | 24.4 | 24.4 | 29.3 | ||

| Max | 9.4 | 9.4 | 10.9 | 11.9 | 13.9 | 13.9 | 16.9 | 16.9 | 21.1 | 21.1 | 26.2 | 26.2 | 31.3 | ||

| h | Nominal | 9.4 | 36 | 45 | 53 | 62 | 62 | 71 | 71 | 90 | 90 | 109 | 109 | 128 | |

| Min | 35.5 | 35.5 | 44.5 | 52.5 | 61.5 | 61.5 | 70.5 | 70.5 | 89.4 | 89.4 | 108.3 | 108.3 | 127.2 | ||

| Max | 37.1 | 37.1 | 46.1 | 54.1 | 63.1 | 63.1 | 72.1 | 72.1 | 91.2 | 91.2 | 110.5 | 110.5 | 129.7 | ||

| d0 | Nominal | 8 | 8 | 10 | 12 | 14 | 14 | 16 | 16 | 20 | 20 | 24 | 24 | 28 | |

| Min | 7.5 | 7.5 | 9.5 | 11.5 | 13.5 | 13.5 | 15.5 | 15.5 | 19.5 | 19.5 | 23.4 | 23.4 | 27.3 | ||

| Max | 8.9 | 8.9 | 10.9 | 12.9 | 14.9 | 14.9 | 16.9 | 16.9 | 21.1 | 21.1 | 25.2 | 25.2 | 29.3 | ||

| d3 | Nominal | 10 | 10 | 12 | 14 | 16 | 16 | 19 | 19 | 24 | 24 | 28 | 28 | 32 | |

| Min | 9.5 | 9.5 | 11.5 | 13.5 | 15.5 | 15.5 | 18.5 | 18.5 | 23.5 | 23.5 | 27.4 | 27.4 | 31.3 | ||

| Max | 10.9 | 10.9 | 12.9 | 14.9 | 16.9 | 16.9 | 19.9 | 19.9 | 25.1 | 25.1 | 29.2 | 29.2 | 33.3 | ||

| Single weight (steel)≈kg | 0.05 | 0.05 | 0.09 | 0.16 | 0.24 | 0.24 | 0.37 | 0.36 | 0.73 | 0.72 | 1.34 | 1.32 | 2.11 | ||

Material

| 304 Chemical Composition(%) | ||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | N≤ |

| 0.08 | 2 | 0.75 | 0.03 | 0.045 | 18.0-20.0 | 8.0-10.5 | 0.1 | |

| 304 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

| 316 Chemical Composition(%) | ||||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | Cu | MO | N |

| 0.017 | 0.98 | 0.25 | 0.0016 | 0.0414 | 16.23 | 10.08 | 0.32 | 2.06 | 0.037 | |

| 316 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

Product Name | Din582 Metric M6 Stainless Steel Eye Nut for Lifting |

Material | Stainless Steel 304/316/316L |

OEM/Custom | YES |

Feature | 1.Corrosion resistant 2.Excellent life cycle 3.Environmentally friendly 4.High-Performance Fastening |

Standard Available | GB, DIN, ISO, ANSI, ASME, IFI, JIS, BSW, AS, Q, HJ, BS, PEN |

Material Available | Stainless Steel Titanium and Titanium Alloy Aluminum |

Packing | Box+Carton +Pallet or as per client's requirement |

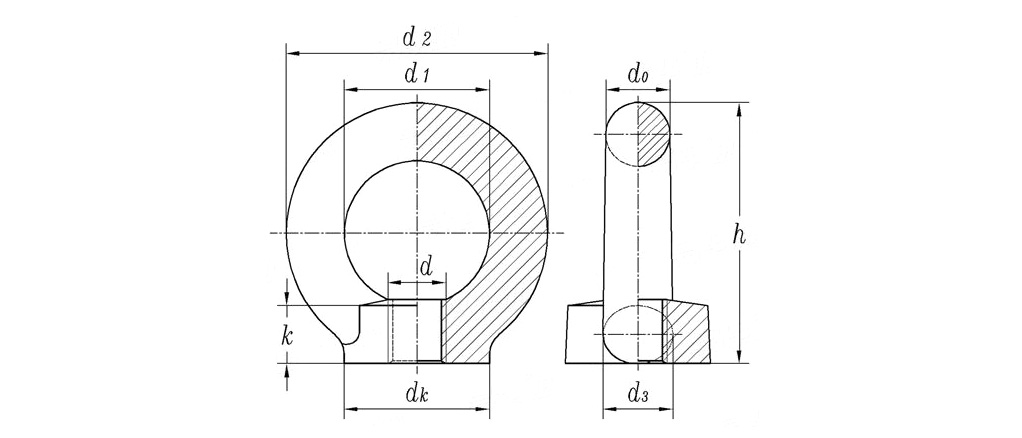

Specification

| Thread size | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | M72×6 | M80×6 | M100×6 | ||

| d | ||||||||||||||

| dk | Nominal | 75 | 85 | 85 | 100 | 100 | 110 | 110 | 120 | 120 | 150 | 170 | 190 | |

| Min | 74.3 | 84.3 | 84.3 | 99.2 | 99.2 | 108.9 | 108.9 | 118.9 | 118.9 | 148.8 | 168.5 | 188.5 | ||

| Max | 76.5 | 86.5 | 86.5 | 101.7 | 101.7 | 112.1 | 112.1 | 122.1 | 122.1 | 152.4 | 173 | 193 | ||

| d2 | Nominal | 126 | 144 | 144 | 166 | 166 | 184 | 184 | 206 | 206 | 260 | 296 | 330 | |

| Min | 125.2 | 143.2 | 143.2 | 164.9 | 164.9 | 182.8 | 182.8 | 204.8 | 204.8 | 258.5 | 294.3 | 328.3 | ||

| Max | 127.7 | 145.7 | 145.7 | 168.1 | 168.1 | 186.4 | 186.4 | 208.4 | 208.4 | 263 | 299.3 | 333.3 | ||

| d1 | Nominal | 70 | 80 | 80 | 90 | 90 | 100 | 100 | 110 | 110 | 140 | 160 | 180 | |

| Min | 68.5 | 78.5 | 78.5 | 88.3 | 88.3 | 98.1 | 98.1 | 107.9 | 107.9 | 137.6 | 157.3 | 177 | ||

| Max | 70.7 | 80.7 | 80.7 | 90.8 | 90.8 | 100.9 | 100.9 | 111.1 | 111.1 | 141.2 | 161.3 | 181.5 | ||

| k | Nominal | 30 | 35 | 35 | 40 | 40 | 45 | 45 | 50 | 50 | 60 | 70 | 80 | |

| Min | 29.3 | 34.3 | 34.3 | 39.2 | 39.2 | 44.1 | 44.1 | 49.1 | 49.1 | 58.9 | 68.8 | 78.8 | ||

| Max | 31.3 | 36.5 | 36.5 | 41.7 | 41.7 | 46.9 | 46.9 | 51.9 | 51.9 | 62.1 | 72.4 | 82.4 | ||

| h | Nominal | 128 | 147 | 147 | 168 | 168 | 187 | 187 | 208 | 208 | 260 | 298 | 330 | |

| Min | 127.2 | 146.2 | 146.2 | 166.9 | 166.9 | 185.8 | 185.8 | 206.8 | 206.8 | 258.5 | 296.3 | 328.3 | ||

| Max | 129.7 | 148.7 | 148.7 | 170.1 | 170.1 | 189.4 | 189.4 | 210.4 | 210.4 | 263 | 301.3 | 333.3 | ||

| d0 | Nominal | 28 | 32 | 32 | 38 | 38 | 42 | 42 | 48 | 48 | 60 | 68 | 75 | |

| Min | 27.3 | 31.3 | 31.3 | 37.2 | 37.2 | 41.1 | 41.1 | 47.1 | 47.1 | 58.9 | 66.8 | 73.8 | ||

| Max | 29.3 | 33.3 | 33.3 | 39.7 | 39.7 | 43.9 | 43.9 | 49.9 | 49.9 | 62.1 | 70.4 | 77.4 | ||

| d3 | Nominal | 32 | 38 | 38 | 46 | 46 | 50 | 50 | 58 | 58 | 72 | 80 | 88 | |

| Min | 31.3 | 37.3 | 37.3 | 45.2 | 45.2 | 49.1 | 49.1 | 57.1 | 57.1 | 70.9 | 78.8 | 86.8 | ||

| Max | 33.3 | 39.5 | 39.5 | 47.7 | 47.7 | 51.9 | 51.9 | 59.9 | 59.9 | 74.1 | 82.4 | 90.4 | ||

| Single weight (steel)≈kg | 2.08 | 3.15 | 3.11 | 5.08 | 5.02 | 6.79 | 6.69 | 9.43 | 9.3 | 18.5 | 27.3 | 36.4 | ||

| Thread size | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | ||

| d | |||||||||||||||

| dk | Nominal | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 50 | 50 | 65 | 65 | 75 | |

| Min | 19.5 | 19.5 | 24.5 | 29.5 | 34.5 | 34.5 | 39.5 | 39.5 | 49.4 | 49.4 | 64.3 | 64.3 | 74.3 | ||

| Max | 20.9 | 20.9 | 25.9 | 30.9 | 36.1 | 36.1 | 41.1 | 41.1 | 51.2 | 51.2 | 66.3 | 66.3 | 76.5 | ||

| d2 | Nominal | 36 | 36 | 45 | 54 | 63 | 63 | 72 | 72 | 90 | 90 | 108 | 108 | 126 | |

| Min | 35.5 | 35.5 | 44.5 | 53.5 | 62.5 | 62.5 | 71.5 | 71.5 | 89.4 | 89.4 | 107.3 | 107.3 | 125.2 | ||

| Max | 37.1 | 37.1 | 46.1 | 55.1 | 64.1 | 64.1 | 73.1 | 73.1 | 91.2 | 91.2 | 109.5 | 109.5 | 127.7 | ||

| d1 | Nominal | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 50 | 50 | 60 | 60 | 70 | |

| Min | 19.1 | 19.1 | 24.1 | 29.1 | 33.9 | 33.9 | 38.9 | 38.9 | 48.8 | 48.8 | 58.7 | 58.7 | 68.5 | ||

| Max | 20.5 | 20.5 | 25.5 | 30.5 | 35.5 | 35.5 | 40.5 | 40.5 | 50.6 | 50.6 | 60.7 | 60.7 | 70.7 | ||

| k | Nominal | 8.5 | 8.5 | 10 | 11 | 13 | 13 | 16 | 16 | 20 | 20 | 25 | 25 | 30 | |

| Min | 8 | 8 | 9.5 | 10.5 | 12.5 | 12.5 | 15.5 | 15.5 | 19.5 | 19.5 | 24.4 | 24.4 | 29.3 | ||

| Max | 9.4 | 9.4 | 10.9 | 11.9 | 13.9 | 13.9 | 16.9 | 16.9 | 21.1 | 21.1 | 26.2 | 26.2 | 31.3 | ||

| h | Nominal | 9.4 | 36 | 45 | 53 | 62 | 62 | 71 | 71 | 90 | 90 | 109 | 109 | 128 | |

| Min | 35.5 | 35.5 | 44.5 | 52.5 | 61.5 | 61.5 | 70.5 | 70.5 | 89.4 | 89.4 | 108.3 | 108.3 | 127.2 | ||

| Max | 37.1 | 37.1 | 46.1 | 54.1 | 63.1 | 63.1 | 72.1 | 72.1 | 91.2 | 91.2 | 110.5 | 110.5 | 129.7 | ||

| d0 | Nominal | 8 | 8 | 10 | 12 | 14 | 14 | 16 | 16 | 20 | 20 | 24 | 24 | 28 | |

| Min | 7.5 | 7.5 | 9.5 | 11.5 | 13.5 | 13.5 | 15.5 | 15.5 | 19.5 | 19.5 | 23.4 | 23.4 | 27.3 | ||

| Max | 8.9 | 8.9 | 10.9 | 12.9 | 14.9 | 14.9 | 16.9 | 16.9 | 21.1 | 21.1 | 25.2 | 25.2 | 29.3 | ||

| d3 | Nominal | 10 | 10 | 12 | 14 | 16 | 16 | 19 | 19 | 24 | 24 | 28 | 28 | 32 | |

| Min | 9.5 | 9.5 | 11.5 | 13.5 | 15.5 | 15.5 | 18.5 | 18.5 | 23.5 | 23.5 | 27.4 | 27.4 | 31.3 | ||

| Max | 10.9 | 10.9 | 12.9 | 14.9 | 16.9 | 16.9 | 19.9 | 19.9 | 25.1 | 25.1 | 29.2 | 29.2 | 33.3 | ||

| Single weight (steel)≈kg | 0.05 | 0.05 | 0.09 | 0.16 | 0.24 | 0.24 | 0.37 | 0.36 | 0.73 | 0.72 | 1.34 | 1.32 | 2.11 | ||

Material

| 304 Chemical Composition(%) | ||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | N≤ |

| 0.08 | 2 | 0.75 | 0.03 | 0.045 | 18.0-20.0 | 8.0-10.5 | 0.1 | |

| 304 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

| 316 Chemical Composition(%) | ||||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | Cu | MO | N |

| 0.017 | 0.98 | 0.25 | 0.0016 | 0.0414 | 16.23 | 10.08 | 0.32 | 2.06 | 0.037 | |

| 316 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

| | Address:4B-D Zone,Intersection of Fenghuang Road and Qishen Road, Fengqiao Town, Nanhu District, Jiaxing City, Zhejiang Province, China 314001. |

| | Mobile/Wechat/Whatsapp: +86-18668329255 |

| | 24h |