DIN7504P

Goshen

GSHS003

Stainless Steel CSK Head Self Drilling Screws

Product Name | Stainless Steel CSK Head Self Drilling Screws |

Material | Stainless Steel 304/316/316L |

OEM/Custom | YES |

Feature | 1.Corrosion resistant 2.Excellent life cycle 3.Environmentally friendly 4.High-Performance Fastening |

Standard | DIN7504P |

Material Available | Stainless Steel Titanium and Titanium Alloy Aluminum |

Packing | Box+Carton +Pallet or as per client's requirement |

Specification

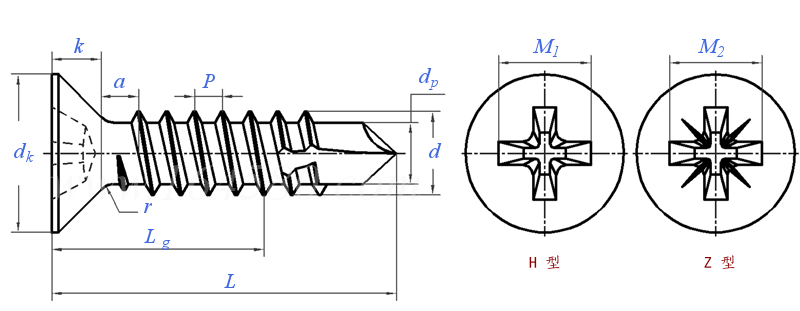

| Thread specification | ST2.9 | ST3.5 | (ST3.9) | ST4.2 | ST4.8 | ST5.5 | ST6.3 | |

| P | Pitch | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 |

| a | Max | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 |

| d k | Max= Nominal | 5.5 | 6.8 | 7.5 | 8.1 | 9.5 | 10.8 | 12.4 |

| Min | 5.2 | 6.44 | 7.14 | 7.74 | 9.14 | 10.37 | 11.97 | |

| k | ≈ | 1.7 | 2.1 | 2.3 | 2.5 | 3 | 3.4 | 3.8 |

| r | Max | 1.1 | 1.4 | 1.5 | 1.6 | 1.9 | 2.1 | 2.4 |

| Slot number | 1 | 2 | 2 | 2 | 2 | 3 | 3 | |

| M 1 | 3 | 4.2 | 4.6 | 4.7 | 5.1 | 6.8 | 7.1 | |

| M 2 | 2.8 | 4 | 4.2 | 4.4 | 5 | 6.3 | 7 | |

| d p | Max | 2.3 | 2.8 | 3.1 | 3.6 | 4.1 | 4.8 | 5.8 |

| Drilling range (board thickness) | 0.7~1.9 | 0.7~2.25 | 0.7~2.4 | 1.75~3 | 1.75~4.4 | 1.75~5.25 | 2~6 | |

Material

| 304 Chemical Composition(%) | ||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | N≤ |

| 0.08 | 2 | 0.75 | 0.03 | 0.045 | 18.0-20.0 | 8.0-10.5 | 0.1 | |

| 304 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200HB |

| 316 Chemical Composition(%) | ||||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | Cu | MO | N |

| 0.017 | 0.98 | 0.25 | 0.0016 | 0.0414 | 16.23 | 10.08 | 0.32 | 2.06 | 0.037 | |

| 316 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

| 316L Chemical Composition(%) | |||||||

| C≤ | Si≤ | Mn≤ | S≤ | P ≤ | Cr | Ni | Mo |

| 0.03 | 1 | 2 | 0.03 | 0.045 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 |

| 316L Mechanical property | ||||||||

| σb(MPa):≥ | σ0.2(MPa)≥ | δ5(%)≥ | ψ(%)≥ | Hardness(HB)(kgf/mm2)] | ρ | SHC | ||

| 480 | 177 | 40 | 60 | ≤187HB;≤90HRB;≤200HV | 7.98g/cm3 | 0.502J/(g*K) | ||

Stainless Steel CSK Head Self Drilling Screws

Product Name | Stainless Steel CSK Head Self Drilling Screws |

Material | Stainless Steel 304/316/316L |

OEM/Custom | YES |

Feature | 1.Corrosion resistant 2.Excellent life cycle 3.Environmentally friendly 4.High-Performance Fastening |

Standard | DIN7504P |

Material Available | Stainless Steel Titanium and Titanium Alloy Aluminum |

Packing | Box+Carton +Pallet or as per client's requirement |

Specification

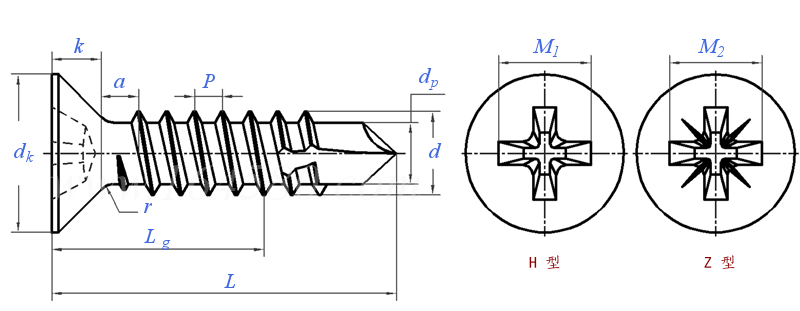

| Thread specification | ST2.9 | ST3.5 | (ST3.9) | ST4.2 | ST4.8 | ST5.5 | ST6.3 | |

| P | Pitch | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 |

| a | Max | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 |

| d k | Max= Nominal | 5.5 | 6.8 | 7.5 | 8.1 | 9.5 | 10.8 | 12.4 |

| Min | 5.2 | 6.44 | 7.14 | 7.74 | 9.14 | 10.37 | 11.97 | |

| k | ≈ | 1.7 | 2.1 | 2.3 | 2.5 | 3 | 3.4 | 3.8 |

| r | Max | 1.1 | 1.4 | 1.5 | 1.6 | 1.9 | 2.1 | 2.4 |

| Slot number | 1 | 2 | 2 | 2 | 2 | 3 | 3 | |

| M 1 | 3 | 4.2 | 4.6 | 4.7 | 5.1 | 6.8 | 7.1 | |

| M 2 | 2.8 | 4 | 4.2 | 4.4 | 5 | 6.3 | 7 | |

| d p | Max | 2.3 | 2.8 | 3.1 | 3.6 | 4.1 | 4.8 | 5.8 |

| Drilling range (board thickness) | 0.7~1.9 | 0.7~2.25 | 0.7~2.4 | 1.75~3 | 1.75~4.4 | 1.75~5.25 | 2~6 | |

Material

| 304 Chemical Composition(%) | ||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | N≤ |

| 0.08 | 2 | 0.75 | 0.03 | 0.045 | 18.0-20.0 | 8.0-10.5 | 0.1 | |

| 304 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200HB |

| 316 Chemical Composition(%) | ||||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | Cu | MO | N |

| 0.017 | 0.98 | 0.25 | 0.0016 | 0.0414 | 16.23 | 10.08 | 0.32 | 2.06 | 0.037 | |

| 316 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

| 316L Chemical Composition(%) | |||||||

| C≤ | Si≤ | Mn≤ | S≤ | P ≤ | Cr | Ni | Mo |

| 0.03 | 1 | 2 | 0.03 | 0.045 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 |

| 316L Mechanical property | ||||||||

| σb(MPa):≥ | σ0.2(MPa)≥ | δ5(%)≥ | ψ(%)≥ | Hardness(HB)(kgf/mm2)] | ρ | SHC | ||

| 480 | 177 | 40 | 60 | ≤187HB;≤90HRB;≤200HV | 7.98g/cm3 | 0.502J/(g*K) | ||